"Most of the people here could get jobs at Porsche or VW, but they're here because they love bikes." - Chris Hilton

As far as history goes, SRAM's Drivetrain Development Centre in Schweinfurt has one of the deepest in our sport. While SRAM itself may have its roots in Chicago in the late 1980s, the story of their drivetrain division goes right the way back to 1895. Ernst Sachs and Karl Fichtel began producing ball bearings and bicycle hubs under the name Fichtel and Sachs in the small, Southern German town. Two years later they expanded into freewheels and by 1911 they already had around 7,000 employees. Yet as the years passed Sachs became more focused on drivetrains and chassis for automobiles and motorcycles, the bicycle division became a small concern amidst a vast company. On the other side of the Atlantic a rapidly growing SRAM realized that a century of expertise would be a huge boost to their range and come 1997 they acquired Sachs' bicycle division.

You can best understand that merger by looking at the product that emerged from it: the SRAM 9.0 SL derailleur. Before the merger SRAM were producing the 9.0 derailleur and Sachs the Plasma derailleur. On holding the products in your hands you can see the way the two designs were put together - the cable routing from the SRAM design combines with the knuckle from the Sachs offering, their engineers took the best of each design and produced a derailleur that was only truly superseded with the introduction of XX1 in 2012. Talking to Bernhard Johanni, his surprise at how it played out is evident - nearly 20 years later he still jokes that he "must have known something useful as they didn't fire me." Most of the older guys in the building have little plaques sitting somewhere in their workspace proudly announcing 15 years of service with SRAM - a sign they were with Sachs before the merger, the knowledge of more than a century of drivetrain components has stayed firmly within the company. For the newly-merged company a new building was needed and with all the heavy machinery acquired with Sachs already in Schweinfurt, it was the obvious location for the new centre. All of SRAM's drivetrain expertise was brought together under one roof in a brand new, custom-built facility.

To think of Schweinfurt in these terms misses the point though. In our sport the growth from a few guys with good ideas to a global organization is a tricky one, especially in people's minds. In a small, community-based sport the idea of a financially successful company spanning the planet is for many an intrusion into our quiet world. The tin foil hat brigade can all too readily imagine the accountants watching over everything as the daily shipment of puppies is brought in to be ground down for oil to keep the hellish machines running. "Most of the people here could get jobs at Porsche or VW, but they're here because they love bikes." That's how drivetrain product manager, Chris Hilton describes the people he works with. You have to take a step back and look at the German economy to put that into perspective. Germany is undoubtedly the engineering powerhouse of the Western hemisphere. They were the first major nation to emerge from the 2008 financial crisis; while the US motor industry lurches from crisis to crisis VW, BMW and Mercedes are powering ahead; as Europe staggers onwards into, well whatever the Eurozone problems are leading too, Germany is more or less carrying the whole continent. In short, now is a good time to be an engineer in Germany. There is money to be made if you're willing to follow it. Yet that money never makes it as far as the bicycle industry. It never has, the reality has always been that by choosing to work on mountain bikes you are choosing to earn tens of thousands of Euros or dollars less than you would if you went into a more mainstream industry.

There is only ever one reason people choose to work in the bike industry - they love bikes. It's a well-worn adage, but it seems to be somewhat forgotten for the people behind the scenes - especially for your drivetrain, which you shouldn't even notice when it is working well. Most of the time nobody asks, "Who designed the ramps and chamfers on my cassette?" They haven't met Matthias and seen the excitement as he hand-cuts a blank cassette in his lab, meticulously sculpting the gear changes you take for granted, which all need to be precisely shaped and placed to make shifting possible at all. Or Robert, who started with Sachs more than 20 years ago, and still keeps the Sachs Quartz derailleur he designed in the late 90s by his desk. Grinning he shows you his legacy, his sole focus for all these years - the derailleur - he has literally worked on nothing but derailleurs and his joy in designing them seems undiminished by time as he shows you his latest creation, one step closer to perfection. What about the Dealer Service Centre, where a room of highly trained and tattooed guys in their early 20s blast loud metal and service up to 250 cases in a single day for customers all over Germany?

In mountain biking we tend to prefer our engineers to be men in sheds or garages. We like them slightly socially awkward, excitable and brimming with clever ideas. Yet what is sometimes forgotten as a company expands is that it was those kind of men who started SRAM. Today those same people still run the company, and, on the evidence of the people you meet in Schweinfurt, they have filled it with people just like them.

Once the decision is made to turn an idea into a product the project is passed to the dedicated team who deal with that component. There is a team for chainrings, another for cassettes, one for rear derailleurs and so on for each sort of component they make here - people who dedicate their working lives to a single component. Development starts with what they know. In the case of their recently-launched direct mount chainrings a blank chainring was the starting point. They knew what the attachment would the crank would have to look like and that it would have a standard number of teeth on the outside, so they started prototyping from there - then the development process shaped the form for performance, strength and weight. Going through the iterations they then started looking at the extremes - the lightest design possible, the strongest, finally working towards the design with the best compromise between the two.

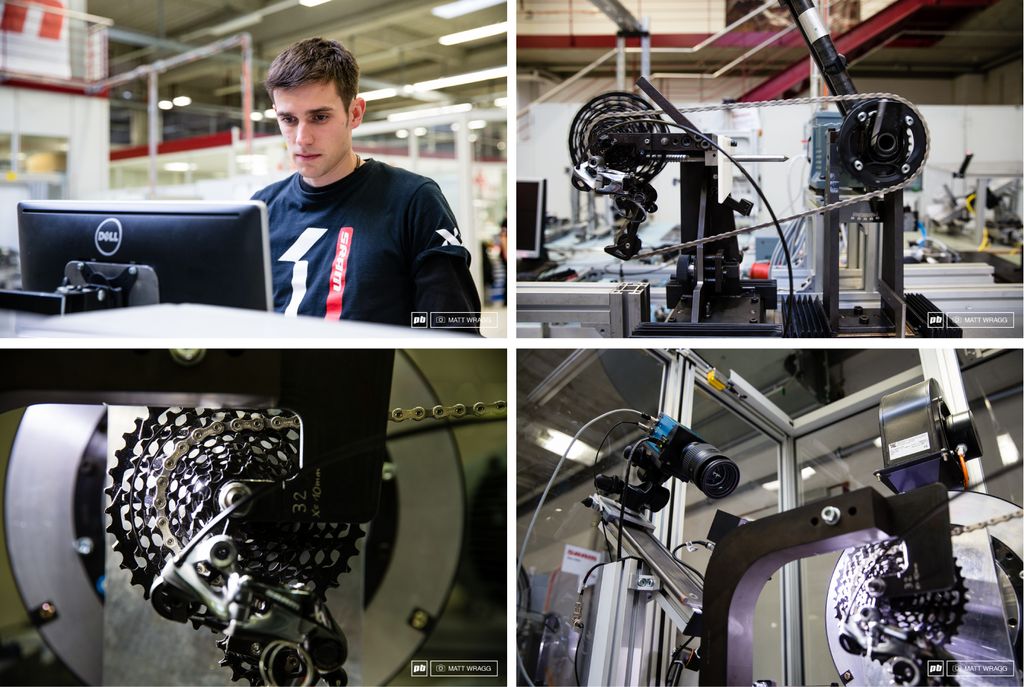

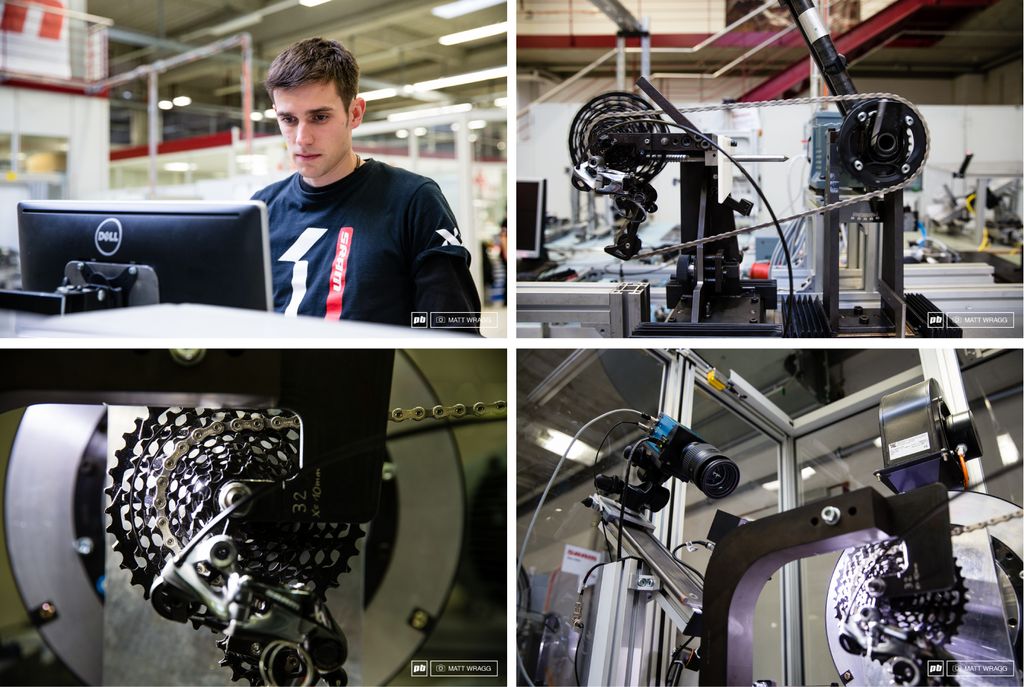

Once they have a design to test the idea comes down here to the prototype lab. It is on these machines that every SRAM drivetrain development since 1997 has taken shape. When we talk about putting resources at the engineers' disposal, this a big part of what that means - there is no need to improvise, almost every manufacturing process can be done here in-house, just on a far smaller scale than a production facility. Many of the guys working in this part of the building are a bit older, with decades of experience in machining to the highest standards. It's fascinating to see their approach to their machines, alongside brand, new cutting-edge CNC machines that look like something shipped straight from a design convention, you have others dating back to the 1950s and a drill all the way from 1928. In many ways it says a lot about German engineering - these machines are still going strong after the best part of a century. As well as the more recognizable machines, there are some here that are a whole lot rarer; like a wire saw that runs on 0.25mm metal wire to cut precise shapes in metal too thin to CNC (apparently it is so sharp you wouldn't even feel it as it cut your finger off) and an EDM cutter.

Some prototypes need input from the engineers before they are ready to move onto the next phase. Cassettes are a good example of this - the very act of changing a gear is part-science, part-art. To make it work you need a complex, interconnected series of ramps and chamfers. The ramps allow the chain to smoothly move up to the sprocket above, and the chamfers both catch the upwards-moving chain, and allow it drop down again. However, to make the cassette work smoothly as a whole is mind-bendingly complicated. Working on a repeating pattern, that pattern needs to repeat and line up across the different-sized sprockets so shifting feels consistent all the way across the block. Working on a hand crank, the cassette is first marked to set the basis for the pattern, then each ramp and chamfer is lovingly sculpted by hand, tested, then re-sculpted until each shift is slick and easy. How difficult this process is can be seen with the XX1 project. Their original idea was that it should feature a 9-36 tooth cassette, but testing showed that a 9 tooth sprocket was both difficult to make work in terms of shifting performance and longevity on the bike, so they backed off to a ten tooth on the small end and added the extra range at the top of the cassette. Hand-cut cassettes are then taken upstairs and modelled on a computer so they can be produced by a machine next time.

Once the prototypes are ready testing begins with the "Wire Donkey." Its name is a joke that doesn't quite translate over from German - although the name still seems fitting. The premise is simple - to test something you first need to know what you are testing for. For example, to understand the forces that go through a crank during hard acceleration they roped in one of their 4X racers and had him do hill sprints on the bike (well, a mountain bike version of this bike which wasn't in the office when we visited). Using that kind of real world data they can then design the most appropriate lab tests to simulate them and repeat them over and over again in a controlled environment.

Once the test team know what they are looking for they head downstairs to the test lab to put the prototypes through their paces. Before testing commences in full the parts are mounted on a hand crank setup that allows them to test the basic functionality - does it all work together? Do the gears shift? Does the chain stay on? When they are sure of that it moves onto they move onto the other machines to test the parts to the their limits and beyond. They are looking to answer questions like: How long will it keep working for? How much force can we put through it in this direction? How much stress can the chain withstand? When it fails, how does it fail? Failure is a big issue that most people don't stop to think about, because if the testing process is done well and they kit is used sensibly, the chances are they won't experience a dramatic failure. All parts have a failure point though, the design process looks to compromise strength and weight - for instance, they could make a near-indestructible chainring if you were happy pedalling around with a kilogram of metal attached to your cranks... The important thing with failure is that it happens in a controlled way. While we were in the lab they put a direct mount ring attached to XX1 cranks through a load test. The ISO standards state that a crank and ring need to be able to withstand a load of 1,500 Newtons - as a matter of policy SRAM far surpass such standards and they loaded the crankset with around three times as much weight. After the test, sure, the cranks were no longer straight and the chainring was pretty heavily deformed, but nothing broke off and the chain actually stayed on the ring. If that had happened on a ride you'd probably have had a nasty landing and you'd be walking home, but you wouldn't have an ankle full of shards of carbon and splintered chainring - a critical difference.

To fully understand what has happened in testing the parts are sent to the measurements lab. In fact, they are sent here before testing for baseline measurements too. Using microscopes, precise 3D modelling and scales so sensitive they can detect the weight of your breath on them, they can detect the precise effect of testing on the parts - for example, using powerful microscopes they can examine how the testing has affected the very make up of the material. Data from the measurements lab is sent up to the design team who compare the results with their 3D models and FEA analysis to make decisions on how the next iteration should look. The whole process to this point will then be repeated, new prototypes will be designed, produced, tested and measured until they reach a point where they feel the part satisfies the goal they set out at the beginning of the project. All of this is accompanied by real world testing too, because as good as the machines are they, the engineers know that nothing can completely substitute for having a part used out on the trail. The testing and measurement phases don't stop with the prototypes either, all the way through the life of a product it samples will come back to these labs as part of the quality control process - working to make sure that what is sold to customers meets the standards they reached in development.

When the engineers reach a point where they have a product that works in the way they want, and meets their strength and weight criteria, the final stage is that it goes to the industrial design team. As brilliant as the engineers undoubtedly are, they consider the product solely in terms of function, and as consumers, if we're paying top dollar for a part, we expect it to look good too. Maybe the best-known example of the industrial design team's work is the XX1 derailleur. On its launch SRAM were showing the media the pre-production prototypes - an angular, industrial-looking metal contraption. In terms of function it was almost identical the derailleur that you see on people's bikes today, yet if you're truthful, would you really want that hanging on the back of a bike you've invested time, love and money into? Industrial design add sex appeal to the engineering. It is their job to turn the solid block of metal into swooping angular designs and add colour to the whole affair. With the XX1 derailleur they cite the Audi R8 as one of their major influences, and as a ridiculous an idea as it may sound at first, when you look at the finished product next to the shapes and colours that influenced them, you can really see how they carried the design language from the car over into a derailleur.

Once the look is finalized, the process moves away from Schweinfurt to SRAMs facilities in Taiwan, where they begin pre-production and then production of the product. The development of a product takes time - the rear derailleur alone for XX1, which featured a complete re-design of their existing products, started in February 2011 and was released to the general public in August 2012. If you run any SRAM drivetrain component on your bike, whether it's a derailleur, shifter, cassette or chainring, these are the people who designed it, and this is how it was developed.Source: Matt Wragg - NAG & PinkBike

______

See all SRAM's products provided by Ride Plus here